Glass Spacer Pads: Essential for Protection During Handling and Transport

While most people know that glass is fragile and requires careful handling and protection, few are aware of the materials used by glass processing plants for this purpose.

Glass Spacer Pads are among the most commonly used protective materials for glass.

These are shock-absorbing cushioning products used in glass packaging. During the storage and transportation of glass, spacer pads create a gap between two glass panes, preventing direct contact. The softness and cushioning properties of the pads reduce friction between the panes, preventing scratches, while the gap created by the pads helps to reduce issues such as mold growth or cracking. This provides critical protection for the glass.

Types of Glass Spacer Pads

Currently, there are two main materials used for glass spacer pads: Cork and EVA.

Spacer pads are also available in two types of adhesion methods: one with adhesive, which sticks to the glass using removable glue, and the other with foam, which adheres via static electricity.

Different materials and adhesion methods can be combined to create four types of glass spacer pads:

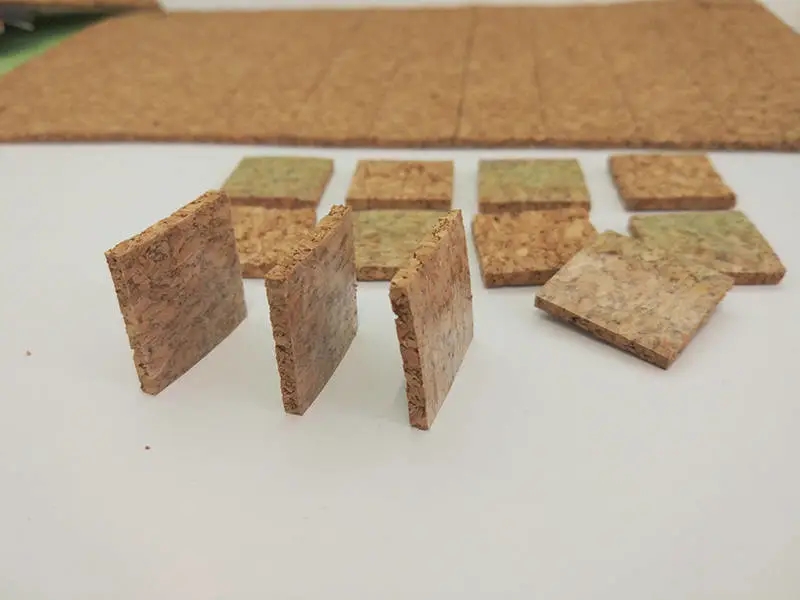

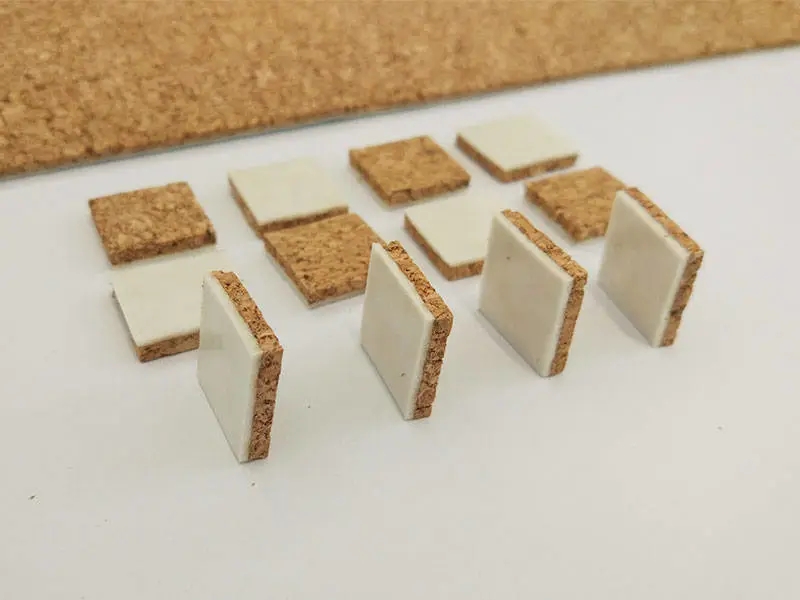

1. Cork with adhesive

2. Cork foam

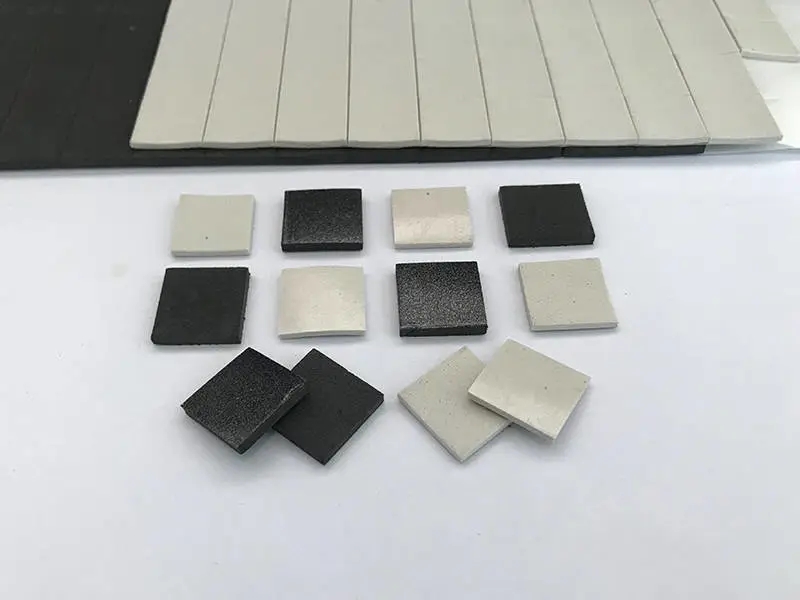

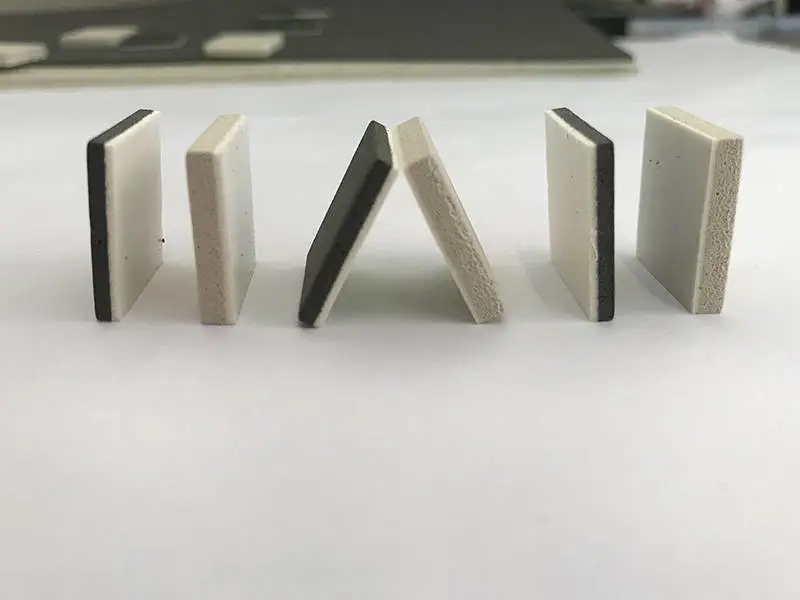

3. EVA with adhesive

4. EVA foam

Features of Cork Spacer Pads

1. Aesthetic and Clean: Cork pads are visually appealing, leaving no residue, safe, and easy to install. They can stick to glass for long periods without leaving marks upon removal.

2. Shock Absorption: Excellent shock-absorbing properties help keep glass intact during transport.

3. Durable: Non-toxic, odorless, pollution-free, and resistant to aging. Cork pads are moisture-resistant, oil-resistant, and capable of withstanding variations in temperature, humidity, pressure, sunlight, frost, and other external environmental factors without deforming or deteriorating.

4. Eco-friendly: Cork is a renewable material, aligning with the demand for green development.

Features of EVA Spacer Pads

1. Water Resistance: Closed-cell foam structure, moisture-resistant, and excellent water-resistant properties.

2. Corrosion Resistance: Resistant to seawater, oils, acids, alkalis, and other chemicals, with antibacterial properties. EVA is non-toxic, odorless, and pollution-free.

3. Processability: No seams, and can be easily thermally pressed, cut, glued, and bonded.

4. Vibration Dampening: High elasticity and tensile strength, providing excellent vibration damping and cushioning performance.

5. Thermal Insulation: Excellent heat insulation and cold resistance, able to withstand extreme temperatures.

6. Sound Insulation: Closed-cell foam structure, providing good soundproofing.

Specifications

Both cork and EVA spacer pads are commonly available in sizes of 15mm x 15mm and 18mm x 18mm.

As for thickness, cork spacer pads typically come in thicknesses of 1.5mm, 2mm, 3mm, 4mm, and 5mm. EVA pads are commonly available in 2mm, 3mm, 4mm, and 5mm thicknesses.

Adhesive-type spacer pads usually refer to the overall thickness, disregarding the adhesive layer. Foam-type pads are typically 1mm thick, meaning that foam-type spacer pads generally require an additional 1mm layer on top of the cork or EVA thickness. For example, a 3+1 spacer pad would consist of 3mm cork or EVA with an additional 1mm foam layer.

Applications

Glass spacer pads are primarily used for protecting the storage and transport of various types of architectural glass, including raw glass, tempered glass, coated glass, insulating glass, laminated glass, and bulletproof glass. Due to their excellent toughness, they are also used in other applications such as doors, windows, mirrors, stone, tiles, cabinets, sliding doors, and furniture.

Contact: Jeff

Phone: +86 15979053680

Tel: +86 15979053680

Email: [email protected]

Add: 1306 Hualong International Building, Xihu District, Nanchang City, Jiangxi Province